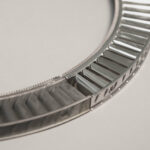

High-Precision Control of Surface Roughness

Precision-engineered parts, such as gas turbine components, leave no room for error concerning surface treatment.

The Micro Machining Process (MMP TECHNOLOGY®) is a surface finishing technology based upon selective filtration of wavelength ranges of roughness, allowing for the production of super precise and selective surface states.

The results are uniform and reproducible: MMP TECHNOLOGY® is an industrial process that ensures total traceability and industrial-grade control of all parameters from start to finish.

MMP TECHNOLOGY® is highly effective on virtually every alloy, regardless of hardness. MMP TECHNOLOGY® can treat parts made from any manufacturing method, including forging, casting, machining, EDM/ECM, and additive layer methods (DMLS, SLM, etc.).

Component types

Characteristics

High-Precision Control of Surface Roughness

MMP TECHNOLOGY® is highly effective on virtually every alloy, regardless of hardness. MMP TECHNOLOGY® can treat parts made from any manufacturing method, including forging, casting, machining, EDM/ECM, and additive layer methods (DMLS, SLM, etc.).

Technical Benefits of Using MMP

- Increased resistance to corrosion

- Reduced friction

- Increased resistance to wear

- Improved aerodynamics

MMP Advantages

- Cost and lead times are predictable and tightly controlled

- Homogeneous finishes are reproduced to industrial standards for each part

- Treated components exhibit superior technical performance

- Ensures industrial-standard traceability and uses certified quality procedures

Added Values

MMP TECHNOLOGY® guarantees high-performing, homogenous, reliable parts.

We strive in all of our services to give the best possible satisfaction to our partners and customers.