Added Values

Filter

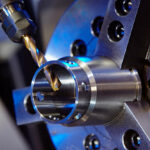

Preparation before PVD (increase PVD adhesion)

The MMP treatment allows for the micro-deburring of cutting edges.

Decrease Roughness after PVD coating

MMP treatment reduces the roughness of the PVD and eliminates droplets, thus improving tool life and operation without changing neither the other properties nor the thickness of the PVD.

No Contamination - Easy Cleanability

The MMP treatment reduces the roughness of a part, thus avoiding particle retention on the surface and obtaining a surface that is easier to clean.

Increase Lifetime

MMP treatment improves all the surface characteristics of the part: roughness, friction, lubrication, homogeneity, etc.

Increase Access to Oil Reserve

The MMP treatment optimises the roughness of the parts and thus reduces friction but also keeps micro-cavities to store oil.

Homogeneity and Reproducibility

MMP processing uses a totally controlled flow to micro-machine the surfaces of the treated parts perfectly homogeneously in the processing chamber.

Decrease Micro Turbulence

The MMP treatment reduces the roughness of Gas turbine compressor components.

Decrease Friction

The MMP treatment micro-machines the surface of the part and reduces the roughness of the part.

Remove EDM Recast Layer

When manufacturing parts by EDM, the electro-erosion burns the surface, creating a layer of Heated affected zone(HAZ).

Controlled Micro-Honing of the Edges

The MMP treatment allows for the micro-deburring of cutting edges.

Do you have a specific need?