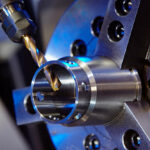

Decrease Roughness after PVD coating

Following the application of PVD to the designated part, an important phase is initiated. It has been observed that the PVD process can generate droplets that significantly increase surface roughness, thereby creating potential fatigue fracture points. However, with the implementation of MMP TECHNOLOGY®, it is possible to significantly reduce the roughness of PVD and eliminate droplets, leading to enhanced tool life and uninterrupted operation. This technology achieves these outcomes without compromising other essential properties or the thickness of the PVD coating.

- Reduces the roughness of the PVD and eliminates droplets

- Treating PVD coatings improves cut quality by reducing friction

- Increased lifetime of the tool without changing its properties