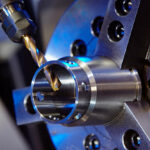

Preparation before PVD (increase PVD adhesion)

PVD coating is a type of thin film coating that enhances the surface of tools by increasing their hardness, improving the friction coefficient, and forming a chemical barrier that protects them from external damage. Achieving optimal performance from this coating requires ensuring that the substrate surface is in its best condition to facilitate good adhesion of the PVD. MMP TECHNOLOGY® is a reliable solution for achieving this goal, as it targets the best roughness profile on the part's surface, ensuring optimal adhesion of the PVD coating used. With optimal adhesion, the lifespan of the coating is extended, providing long-term benefits for the tool.

- Controlled and repeatable edge micro-honing

- Superior surface preparation before coating improves the adhesion of thin coatings (i.e., PVDs)

- Treating PVD coatings improves the cut quality by reducing friction

- Increased lifetime of the coating