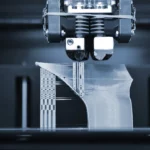

The Finishing Solution for the Next Generation of Manufacturing

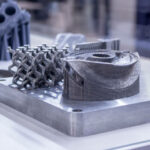

The MMP TECHNOLOGY® is particularly well suited to finishing parts produced using Additive Manufacturing, such as Powder Bed, DMLS, EBEAM or Binder Jet, etc.

With over 19 years of real experience in finishing AM parts, the MMP TECHNOLOGY® is one of the most used finishing technologies by the biggest users of AM in the USA, Europe, India, and Japan.

The Micro Machining Process (MMP®) continually reproduces unrivaled consistency and homogeneity adapted to the specific needs of Additive Manufacturing.

MMP is a surface finishing technology based upon selective filtration of wavelength ranges of roughness. Thus, it allows highly customized part finishing to different levels of roughness.

Parts made by AM can pose a particular challenge, due to the in-homogeneity in their roughness levels. MMP’s unique process is uniquely suited to overcoming this challenge.

The results are both uniform and reproducible: MMP is an industrial process that ensures total traceability and industrial-grade control of all parameters right up to the final finish. MMP delivers proven results on the most complex geometries and the hardest of alloys.

MMP TECHNOLOGY

MMP TECHNOLOGY® is highly effective, regardless of the manufacturing technology used to produce the parts. It allows highly customized part finishing to different levels of roughness. This uniqueness of the MMP is suitable to AM, as parts made by AM pose a particular challenge, due to the in-homogeneity in their roughness levels.

Component types

Characteristics

High-Precision Control of Surface Roughness

The finishing solution for a promising technology. The MMP TECHNOLOGY® is particularly well suited to finishing parts produced using Additive Manufacturing, such as Laser sintering, DMLS, EBEAM, or Binder Jet.

Technical Benefits of Using MMP

- Increased resistance to corrosion

- Reduced friction

- Increased resistance to wear

- Improved aerodynamics

MMP Advantages

- Costs and lead times are predictable and tightly controlled

- Homogeneous finishes can be reproduced to industrial standards for each item

- Treated components can exhibit superior technical performance

- Ensures industrial-standard traceability and uses certified quality procedures.

Added Values

The MMP TECHNOLOGY® treatment brings many added values. These are characterized by their guarantee of homogeneity, performance and reliability, for all the industries concerned by the MMP® process.

We strive in all of our services to give the best possible satisfaction to our partners and customers.