BinC Industries France SAS

AS9100:D / JISQ 9100:2016 / EN 9100:2018

BinC Industries France SAS

ISO 9001 : 2015

Microtek Finishing

Registration Letter / ITAR M37999

Microtek Finishing

NADCAP Cert

Microtek Finishing

ISO 13485 : 2016

Microtek Finishing

ISO 9001 : 2015 / AS9100D

INFINI India

ISO 9001 : 2015

INFINI India

ISO 13485 : 2003

Infini Japan

JISQ9100:2016 and JIS Q 9001:2015

High Precision Control of Surface Roughness

High Precision Control of Surface Roughness

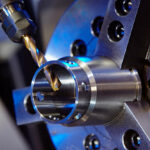

Our super-finishing process, MMP TECHNOLOGY® (Micro Machining Process), utilizes a unique physical-catalytic mechanical treatment of parts. The MMP TECHNOLOGY® process selectively filters the surface roughness to achieve our customer’s specific objectives.

MMP TECHNOLOGY® achieves unparalleled results through detailed analysis of the initial surface to determine the treatment parameters.

MMP TECHNOLOGY® quality certifications

The particularity of MMP TECHNOLOGY® is the mastery of the fine analysis of the initial surface to determine the treatment parameters according to the client’s goals.

BinC Industries France SAS

AS9100:D / JISQ 9100:2016 / EN 9100:2018

BinC Industries France SAS

ISO 9001 : 2015

Microtek Finishing

Registration Letter / ITAR M37999

Microtek Finishing

NADCAP Cert

Microtek Finishing

ISO 13485 : 2016

Microtek Finishing

ISO 9001 : 2015 / AS9100D

INFINI India

ISO 9001 : 2015

INFINI India

ISO 13485 : 2003

Infini Japan

JISQ9100:2016 and JIS Q 9001:2015

MMP TECHNOLOGY

MMP Technology

MMP Technology is an innovative, world-class super-finishing process whose selective removal of roughness achieves control of super-finishes with incomparable homogeneity and reproducibility.